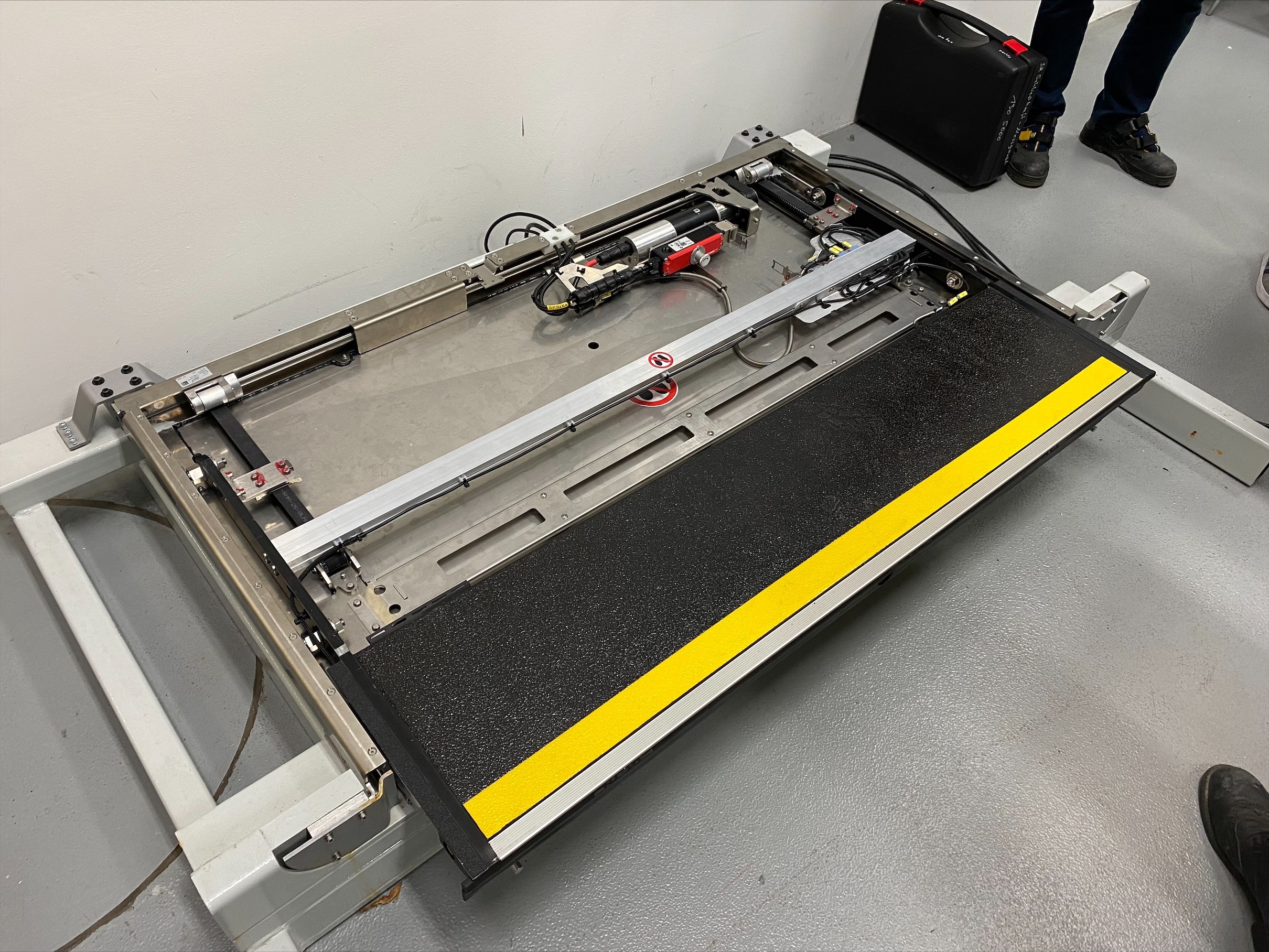

An automatic sliding step that will transform accessibility on the Tyne and Wear Metro’s new trains can be revealed for the first time this week.

The sliding step is a key feature of the new £362m Metro fleet, making life easier for thousands of customers when boarding and alighting by eliminating the gap between the train and the platform edge.

They will be located at every door of the new trains, making boarding easier for Metro’s 50,000 wheelchair customers as well as people with children’s buggies, luggage or bicycles.

The sliding step will automatically deploy from beneath the door sill every time the new Metro train pulls into a station, closing the gap between the platform. It then automatically retracts before the doors close and the train pulls away.

New photos released today show the new boarding system, passenger saloon and driver cab doors being put through their paces as final assembly of the new Metro trains continues.

Both the sliding step and the doors are being made by a company called Bode Die Tur, who specialise in the development and production of electronic door and boarding systems at their factory in the city of Kassel in Hessen, central Germany – which has recently been refitted following severe flash flooding in the region in 2019.

Metro’s operator, Nexus, and the Swiss train builder, Stadler, have conducted an official inspection of this transformative piece of technology. The visit to the Bode factory was a chance to test the sliding step and doors ahead of them going into full production.

When the sliding step and door systems are completed they will be transported to the Stadler assembly line for installation on each of the 46 new trains.

New Fleet Project Manager at Nexus, Sarah McManus, said: “It was fantastic to see the new automatic sliding step in operation. This piece of technology is a key feature of the new Metro train fleet that will transform accessibility for thousands of customers.

“The sliding step works by providing seamless boarding from platform to train. It removes the gap between the train and the edges of the Metro platform when it deploys.

“We got the chance to inspect the sliding step and the new train doors on what is called a first article inspection of the production line over in Germany. Bode have an excellent track record and will be supplying the boarding system to Stadler as final assembly of our new trains progresses.

“We are delighted to share the first images of the Metro’s sliding step and we looking forward to seeing it in operation again when the first new train arrives in our region at the end of the year.”

Nexus finalised the design options for the new Metro trains in June 2021 after an unprecedented 23,000 responses from customers, employees and specialist user groups.

Stadler is making 46 new Metro trains for Nexus, with the first new unit set to arrive at the end of this year.

Stadler are currently fitting the main interior components on the new Metro trains as part of the final assembly process. They will deliver the first new train at the end of the year for testing and driver training, with a view to it entering customer service in the summer of 2023.

The works include the installation of wheels, seats, equipment cases, piping, wiring, flooring, windows and other internal furnishings. Works are taking place at Stadler’s state-of-the-art production line in St Magrethen in northern Switzerland.

The new trains, which will be 15 times more reliable and will cut energy consumption by 30%, will have modern features including charging points, air conditioning and a step-change in accessibility.

Stadler is also in the process of building a new £70m Metro depot at Gosforth as part of the new fleet project.

Find out more at www.nexus.org.uk/newmetrotrains